Types of Roofing Sheets to Suit Extreme Weather Conditions

Roofing sheets are the modern way to protect your property from severe environmental conditions like heavy snow or extreme temperatures. They come in a wide range of designs, shades, and materials that offer numerous benefits and enhance the overall aesthetic appearance of your building.

When choosing roofing sheets, it is essential to consider the weather conditions in your region, the architectural style of your home, and your budget to choose the right option. Opt for a professional roofing contractor in Norwich to avoid any negative impacts.

Different Types of Roofing Sheets:

Each roofing material is suited to perform better in certain conditions, and some materials are more suitable for specific applications or building styles to improve the overall roof strength.

Let's explore some common types of roofing sheets and discover the possibilities they offer for enhancing the form and function of our built environments.

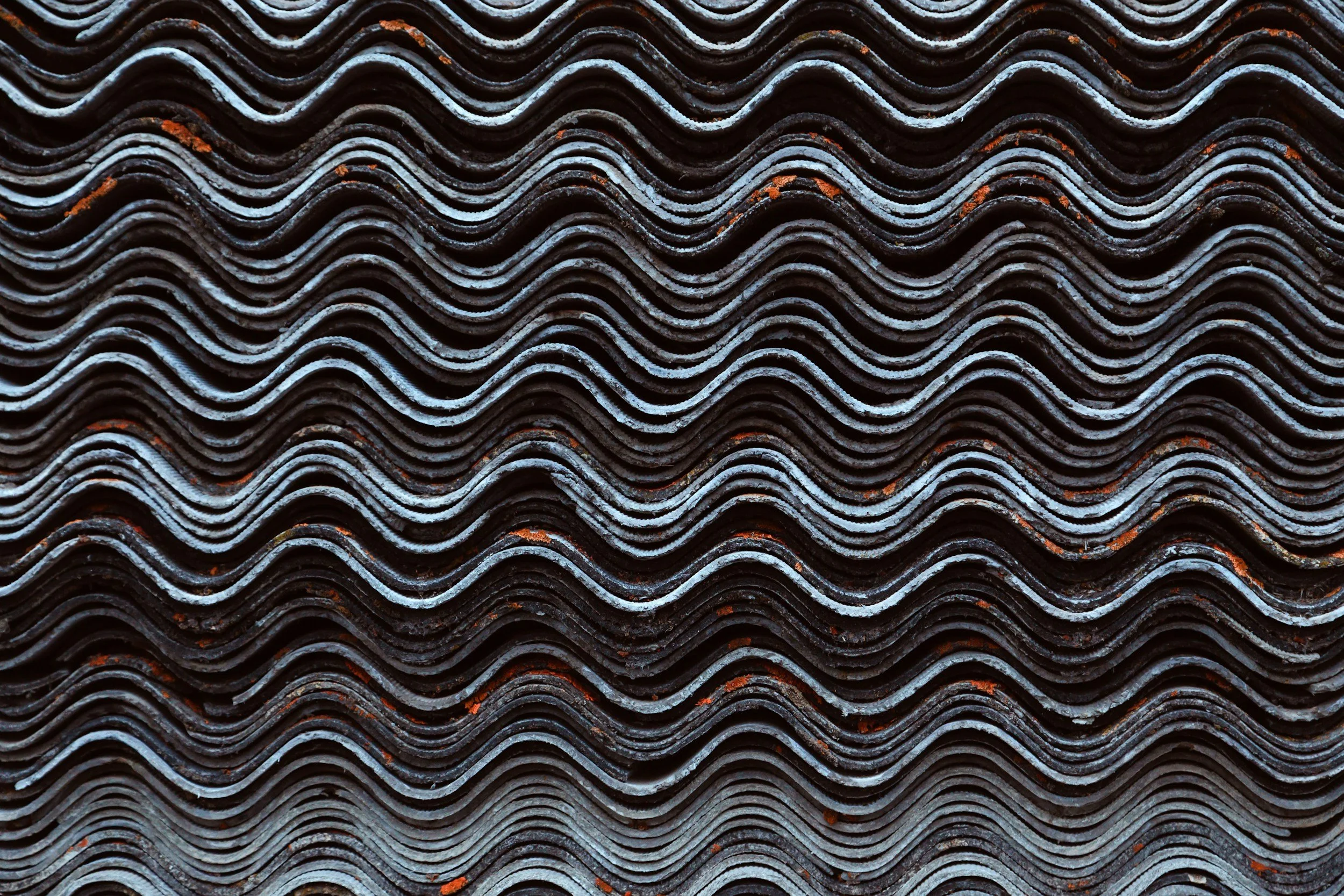

Corrugated Roofing Sheets:

Known for its wave-like pattern, corrugated sheets feature parallel grooves and ridges which make them strong and versatile. These coverings can transmit weight more uniformly, which makes them more resilient and sturdy because of their curvature. They are made of a variety of materials, including PVC, galvanised steel, and aluminium. Each roofing material has its own unique advantages and features that make it suited for different applications. Corrugated sheets are mostly used for carports, gardens, sheds, commercial warehouses, agricultural and industrial buildings.

Pros:

Lightweight and easy to install

Offer high impact resistance and can withstand extreme weather

Allow natural light to penetrate while blocking harmful UV rays, making them energy-saving

DIY-friendly

Require no specialist tools or techniques

Low maintenance, occasional inspection for damage.

Available in various materials and colours.

Cons:

Can be noisy during rain or hail.

May require regular cleaning to prevent debris buildup in the corrugations.

Can be prone to rust if made of metal and not properly maintained.

Metal sheets:

Sheets of metal roofing are composed of a variety of components, including steel, copper, zinc, and aluminium. Large buildings often use metal covering because of their quick installation process. They have a 25-year lifespan with 100% recyclable property.

Because of their capacity to reflect solar radiation, these roofing sheets can lower energy and cooling expenses.

The colour and polish of metal sheeting can provide a rustic or sleek, contemporary appearance.

Pros:

Incredibly hard-wearing, strong, and weather-resistant

Withstand high temperatures and harsh winds with ease

Durable with a 50-year manufacturer's guarantee

Low maintenance, requiring little upkeep across a long lifespan

Simple to install by a roofer and can be completed in a few hours with the basic tool.

Cons:

Can be more expensive

Prone to denting when heavy objects fall on them.

Susceptible to corrosion, especially in coastal areas with high salt content in the air.

Bitumen roof sheets

There are several types of bitumen sheets that can be purchased, such as roll, built-up, and modified roofing. They are also referred to as asphalt roofing sheets and are composed of a bitumen combination with other components like polyester or fibreglass. Because they are so good at waterproofing, they are mostly used on flat and low-slope roofs. Usually consisting of layers fused together with hot glue, they guarantee a strong bond between neighbouring membranes. Moreover, an overlap of around 100 mm is supplied for efficient waterproofing.

Although the recycling procedure for bitumen roofing sheets is not as well-established as it is for metal roofing sheets, bitumen coverings have a lifespan of ten to fifteen years. These sheets can be topped with reflective coatings to improve energy efficiency by lowering heat gain and energy usage.

Pros:

Cost-effective option

Require Low maintenance

Cons:

Not as environmentally friendly as some other options due to its petroleum-based composition.

Susceptible to heat damage and may soften in extreme temperatures.

May emit odours, particularly when new or in hot weather.

Polycarbonate roofing sheets

These sheets come in different thicknesses and grades, offering a lighter alternative to steel while maintaining strong resistance against breaking and splitting. Fixing them with screws and support rods makes them easy to work with and weld. They come in a variety of shades and levels of opacity, and polycarbonate sheets serve various purposes, such as skylights, canopies, and greenhouses.

Pros:

Valued for Lightweight nature

Can be easily cut with sharp scissors or circular saws

Cons:

Prone to scratching, which can reduce transparency over time.

Fibre Cement Roofing Sheets

A semi-compressed corrugated profile for great strength and durability is formed by a composite blend of cellulose fibres, cement, and sand in fibre cement sheets. They find widespread use in both roofing and cladding applications.

These sheets do not easily burn as they are non-combustible, making them an excellent choice for buildings requiring adherence to strict fire safety standards or located in fire-prone areas. They also resist rust and deterioration when exposed to moisture, thereby prolonging the lifespan of roofs and cladding while minimising maintenance requirements.

Moreover, fibre cement sheets provide effective acoustic insulation, reducing noise levels and enhancing overall building comfort by mitigating noise pollution. With compliance to UKCA mark approval and adherence to standards such as BS EN ISO 9001 and BS EN 494 for Class 1X sheeting, they ensure quality and reliability.

These sheets are reinforced with polypropylene strips to offer maximum impact strength without compromising their appearance, durability, or practicality.

Pros:

Highly sustainable especially in UK weather conditions

Highly breathable

Exceptional performance, longevity, and low maintenance requirements

Cons:

Contains asbestos in older versions, posing health risks if damaged or disturbed.

Can be heavy, requiring additional structural support.

Installation may require special tools and expertise.

Bamboo Sheets:

Usually, bamboo strips are bound or woven together to provide a sturdy, waterproof surface for roofing sheets. They can be installed using conventional methods and are suitable for use in both pitched and flat roof systems. The remarkable insulating qualities of bamboo coverings are one of their best features. Because they are inherently insulators, they help retain warmth in cold climes and decrease temperatures in hotter ones.

Bamboo sheets have practical advantages, but they also have aesthetic value. Their organic, natural appearance improves the appearance of any building. Bamboo roof coverings have a lifespan of over 50 years, making them incredibly durable. They are resistant to insects, rot, and decay and can withstand extreme weather conditions, including high winds and heavy snow.

Pros:

Promote sustainability.

Reduce energy costs

Moisture resistance

Environmentally friendly

Renewable resource

Cons:

Susceptible to mould and decay

Limited availability

Can be prone to warping

Galvanised Iron sheet:

Hot-dip galvanization is the procedure used to coat mild steel in a layer of zinc to create roof coverings composed of galvanised iron. By submerging the steel sheets in a bath of molten zinc throughout this process, a protective layer is formed on the steel's surface, increasing its strength and preventing corrosion.

This on both sides of iron is normally at least 120g/m2, and the thickness of the sheets typically ranges from 0.35mm to 0.7mm. The corrugations also differ in depth and pitch; the most typical combination is 18 mm in depth and 76.2 mm in pitch.

Point to Remember:

The seller may attempt to sell electro-galvanised steel, which has a thinner zinc coating. Thus, it is crucial to measure it with a coating thickness gauge when buying galvanised iron roofing sheets.

It is necessary to make sure that the handling personnel wear protective boots and gloves to prevent injuries. Also, first aid supplies must be readily available at the loading and unloading sites.

Pros:

Good material stiffness

Different sizes options

Easily applied

Cons:

Can rust over time if the galvanised coating is compromised.

Conclusion:

Roofing sheets play a vital role in protecting structural integrity and enhancing the style of your property. Each has unique characteristics and benefits that help architects, builders, and homeowners to make informed decisions for their projects more effectively. Hire a professional roofer to select the best suitable roofing sheet as per the UK weather conditions.