Clear Communication: How Electric Wire Stickers Serve as Informational Tools

In the intricate realm of electrical systems, clear communication is paramount to ensuring safe and efficient operations. Amidst the intricate maze of wires and cables, electric wire stickers emerge as invaluable informational tools, facilitating seamless communication and enhancing overall system functionality.

Introduction

Effective communication is the cornerstone of any successful electrical installation or maintenance endeavor. As systems become increasingly complex, the need for clear identification and labeling of individual components becomes more crucial than ever. Wire and cable label play a pivotal role in this regard, serving as a bridge between the physical infrastructure and the human operators, enabling precise comprehension and streamlined operations.

Enhancing Safety through Clear Identification

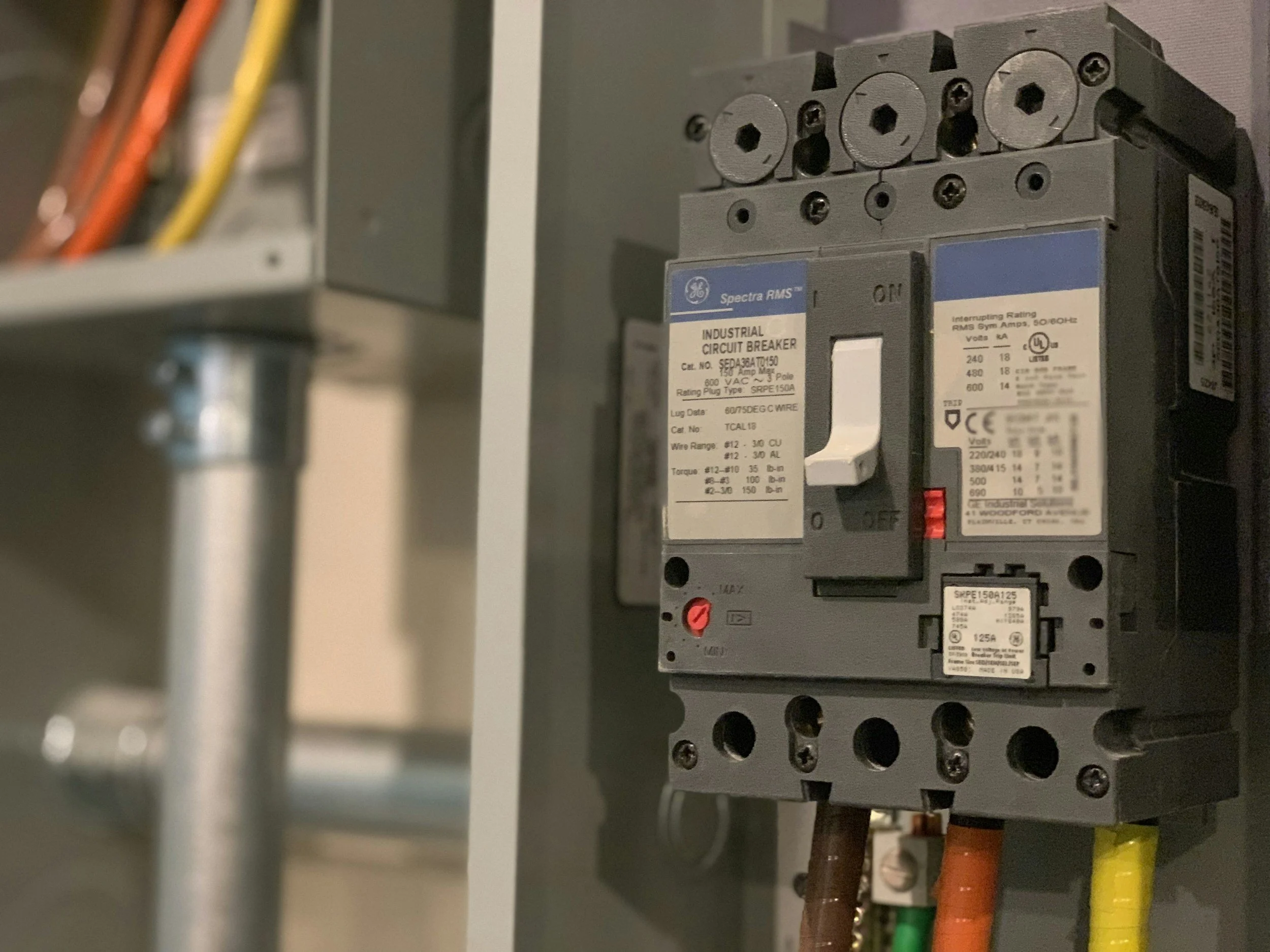

One of the primary functions of electric wire stickers is to mitigate the risks associated with electrical hazards. By clearly labeling wires and cables, these informational tools facilitate the safe handling, maintenance, and repair of electrical systems. Accurate identification minimizes the potential for human error, preventing accidental contact with live wires and reducing the likelihood of costly disruptions or dangerous incidents.

Moreover, wire stickers aid in the implementation of lockout/tagout procedures, ensuring that no unauthorized personnel inadvertently tamper with or energize systems during maintenance or repair operations. This level of clear communication fosters a culture of safety, protecting both personnel and equipment from potential harm.

Streamlining Troubleshooting and Maintenance

In the realm of electrical systems, efficient troubleshooting and maintenance are paramount to ensuring uninterrupted operations and minimizing downtime. Electric wire stickers play a pivotal role in this regard, serving as visual cues that expedite the identification of specific wires and cables within a larger network.

By clearly labeling each component, technicians can quickly locate and isolate the source of any issues, reducing the time and effort required for diagnosis and repair. This streamlined process not only enhances operational efficiency but also contributes to cost savings by minimizing unnecessary disruptions and lost productivity.

Regulatory Compliance and Industry Standards

The use of electric wire stickers extends beyond mere convenience; it is often a mandatory requirement prescribed by various safety regulations and industry standards. Adhering to these guidelines not only ensures compliance but also fosters consistency and interoperability across different electrical systems and installations.

By adopting standardized labeling practices, electrical professionals can communicate effectively with colleagues, contractors, and regulatory bodies, facilitating seamless collaboration and ensuring that installations meet the highest safety and quality standards.

Customization and Durability of Electric Wire Stickers

One of the key advantages of electric wire stickers is their versatility and durability. These informational tools can be customized to meet the specific needs of various applications, ranging from industrial settings to residential installations. Manufacturers offer a wide array of options, including diverse materials, sizes, and printing methods, allowing for tailored solutions that cater to unique environmental conditions and operational requirements.

Furthermore, modern wire sticker materials are designed to withstand harsh environments, resilient against factors such as extreme temperatures, moisture, chemicals, and abrasion. This durability ensures that the information conveyed remains legible and accessible throughout the lifespan of the electrical system, minimizing the need for frequent replacements and maximizing the longevity of the investment.

Conclusion

In the intricate tapestry of electrical systems, clear communication is not merely a luxury but a necessity. Electric wire stickers serve as invaluable informational tools, fostering safety, efficiency, and compliance within this critical domain. By enhancing identification, streamlining troubleshooting and maintenance, and adhering to industry standards, these unassuming labels play a vital role in ensuring the smooth operation of electrical installations.

As technology continues to evolve and systems become increasingly complex, the importance of electric stickers will only grow. Their ability to convey critical information, facilitate clear communication, and contribute to overall system reliability solidifies their position as an indispensable component in the ever-advancing electrical industry.